TYPE:

TYPE:Secondary treatment.

CAPACITY:93,000 gallons per day (gpd).

TREATMENT PROCESSES:Comminution, extended aeration biological treatment, secondary clarification, Nitrification/Denitrification, and chlorination.

The treated wastewater is used for irrigation over an on-site disposal area.

BACKGROUND

The Lake Hughes Community Wastewater Treatment Facility (CWTF) is located at 17201 Elizabeth Lake Road, Lake Hughes, California. The plant is operated by the Los Angeles County Department of Public Works. The plant treats domestic wastewater on behalf of the community of Lake Hughes in the unincorporated county area and serves an estimated population of 450 and 320 for the Painted Turtle Camp.

WASTEWATER TREATMENT PROCESSES

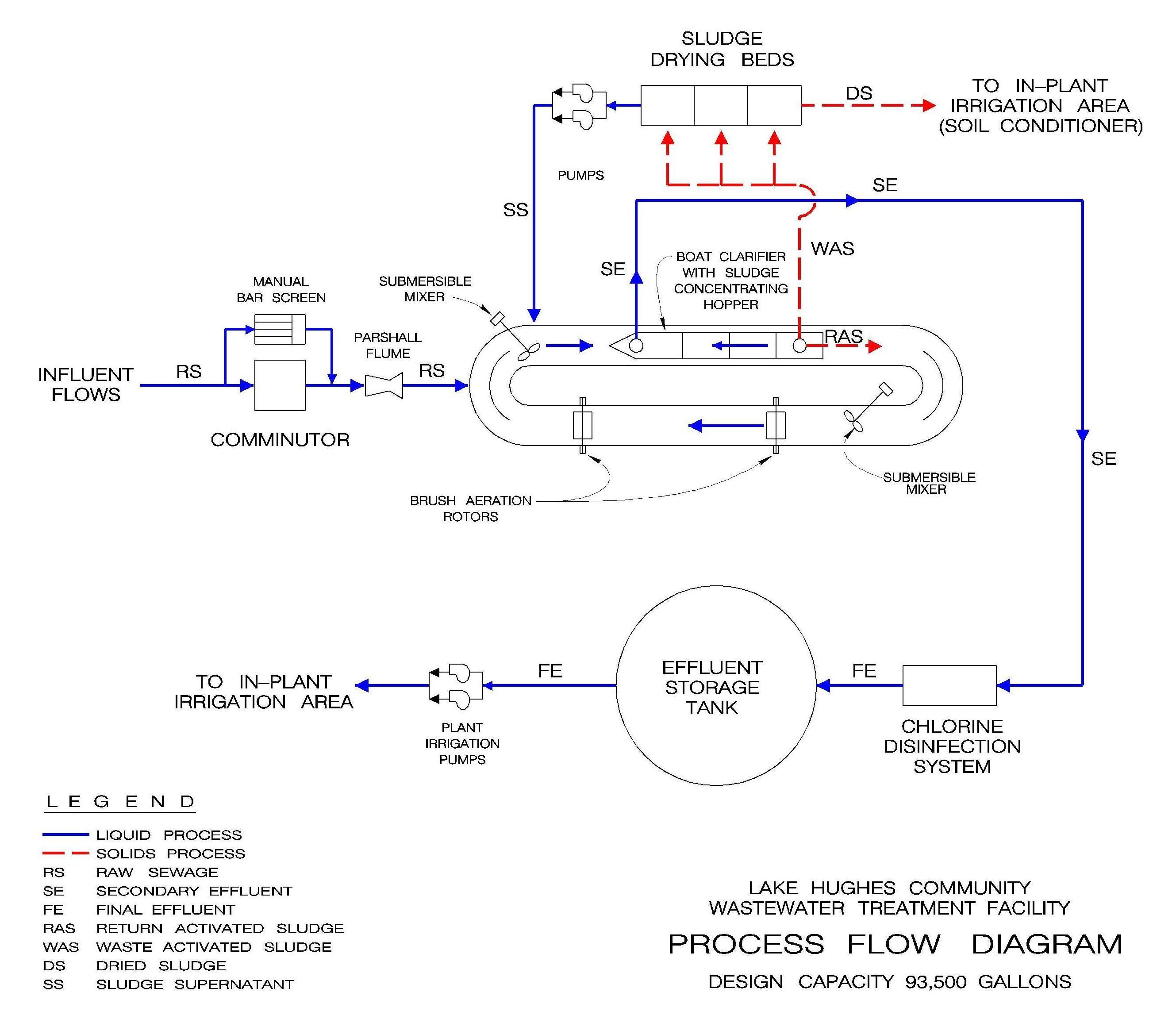

The Lake Hughes CWTF is a secondary wastewater treatment facility. It was designed for an average dry weather flow of 93,500 gallons per day (gpd). Treatment processes include comminution, extended aeration biological treatment in an oxidation ditch, secondary clarification, chlorination, effluent disposal, and sludge drying. Figure 5-1 is a Flow Diagram of the treatment process. Following is a brief discussion and description of the treatment plant processes.

Figure 5-1. Flow Diagram

Preliminary Treatment

Preliminary treatment consists of an influent channel, comminutor and flow meter (Photo 5-1). The flow is pumped to the treatment plant from a 6-inch force main into the influent channel and flows to the comminutor. The comminutor cuts and shreds large pieces of material into smaller pieces. This minimizes clogging and plugging problems in the downstream treatment processes. A by-pass channel with a manual bar rack is provided if the comminutor needs to be serviced. The influent flow is measured by a parshall flume downstream from the comminutor and the bar rack.

Photo 5-1. Influent Channel and Comminutor

Secondary Treatment

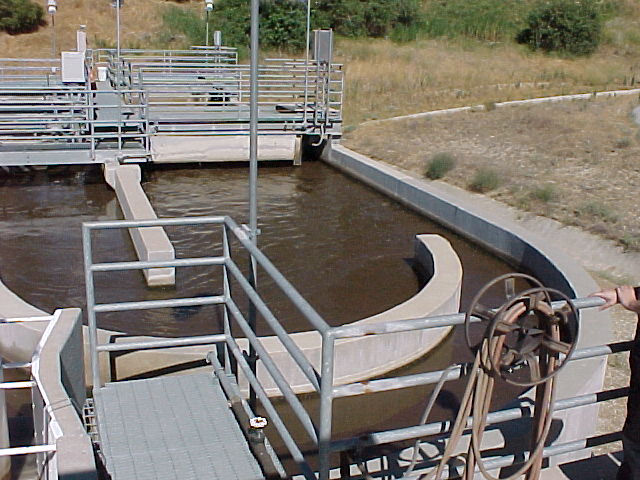

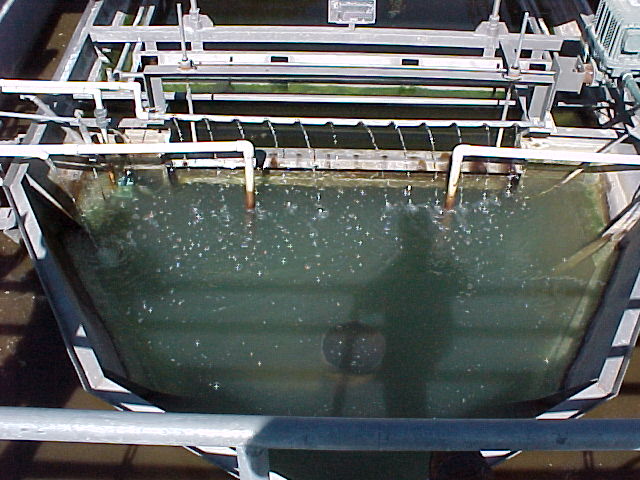

Secondary treatment consists of extended aeration biological treatment in an oxidation ditch (Photo 5-2) followed by secondary clarifiers. The wastewater proceeds from the comminutor by gravity to the oval-shaped oxidation ditch. Brush aerators circulate the wastewater around the oxidation ditch at a velocity of approximately 1 feet per second and also provide aeration. In the oxidation ditch, microorganisms remove organic material from wastewater and form as settleable solids. After the oxidation ditch, the flow is distributed by a weir to the intra-channel boat clarifier (Photo 5-3) where the solids are settled and returned to either the oxidation ditch (return activated sludge) or to the sludge drying beds (waste activated sludge).

Photo 5-2. Oxidation Ditch Photo

5-3. Intra-Channel Boat Clarifier

Nitrogen Removal

Nitrogen reduction is achieved in the oxidation ditch using sequence of alternating aerobic (with oxygen) and anoxic (without oxygen) cycles. In the aerobic mode, the brush aerators provide both aeration and mixing simultaneously and the incoming ammonium-nitrogen is converted to nitrate-nitrogen. During the anoxic mode, aeration is stopped and the nitrate-nitrogen is removed by the microorganisms. The aerobic/anoxic cycle times are manually adjusted to optimize the process performance.

Disinfection

The secondary effluent flows to the chlorine contact chamber, which consists of an underground network of pipes to ensure adequate contact time for disinfection. A calcium hypochlorite tablet feeder (Photo 5-4) dispenses the disinfecting agent (chlorine), which kills the microorganisms in the effluent.

Photo 5-4. Chlorine Tablet Feeder

Effluent Disposal

The treated wastewater flows to a 2.2 million gallon storage tank (Photo 5-5) prior to being spray irrigated on-site over an estimated 6.7 acres of disposal area (Photo 5-6). The plant site is a fenced and restricted area. Also, the storage tank provides 23 days of emergency storage (based on design flows) in case of inclement weather.

Photo 5-5. Effluent Storage Tank

Photo 5-6. Spray Irrigation Field

Sludge Disposal

Waste activated sludge is gravity fed to three drying beds on-site. After drying, the biosolids (dried sludge) are removed from the beds and used as soil amendment on the plant grounds.